1-TO-3 – SXL IASS EXPO PAVILIONS 2019

All images (c) Jan Brütting / Structural Xploration Lab, EPFL

1-TO-3 – SXL IASS EXPO PAVILIONS 2019

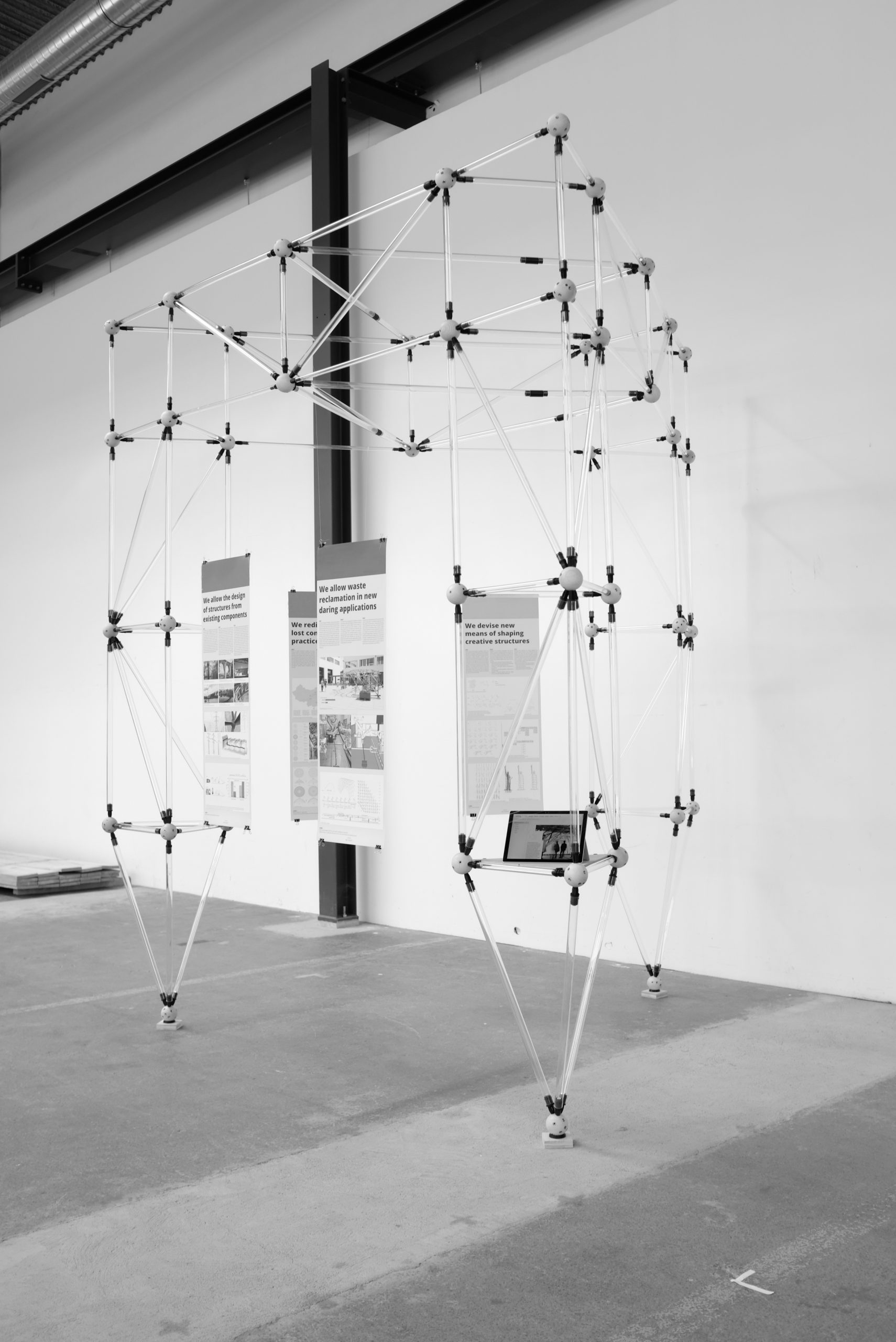

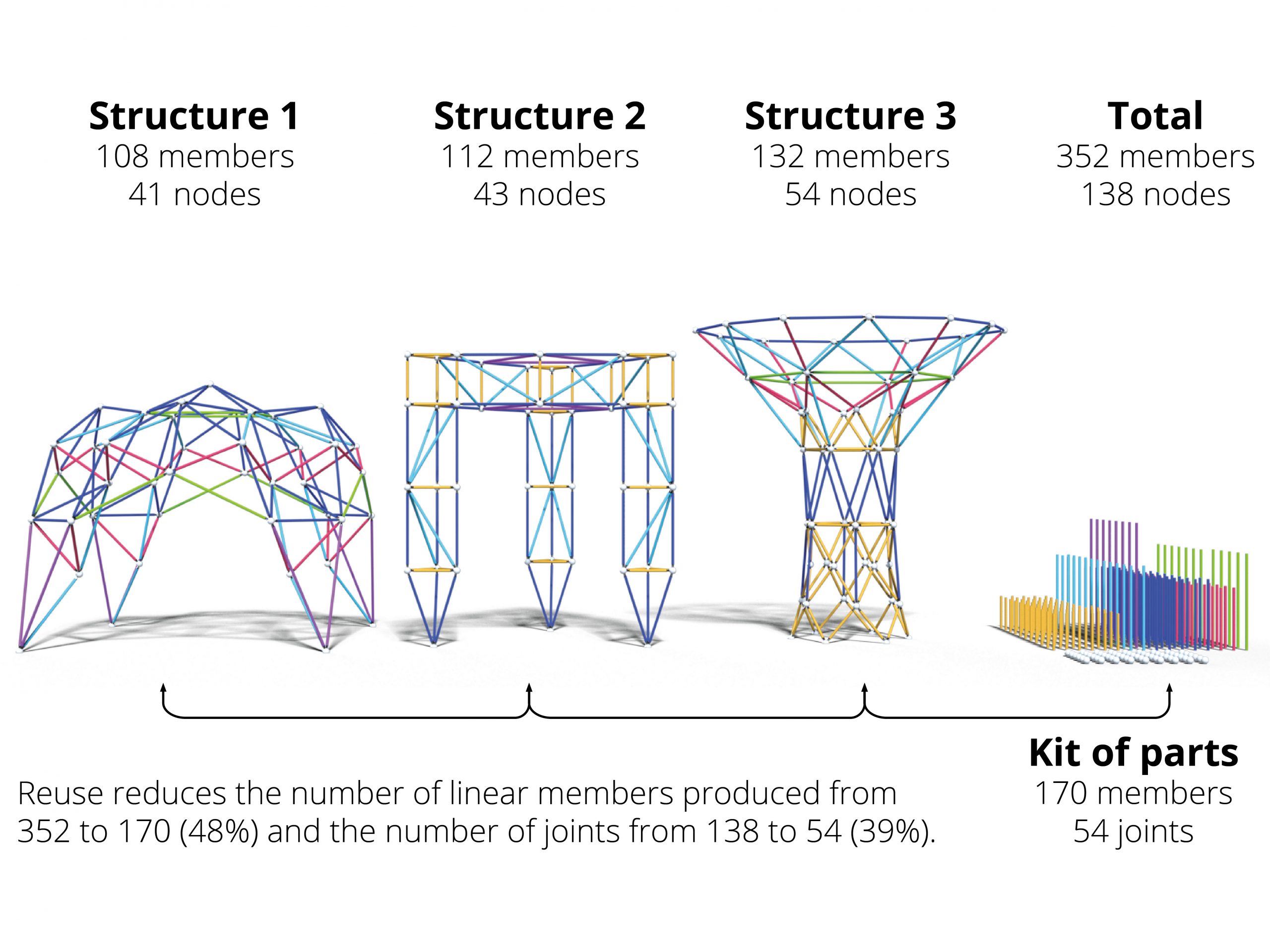

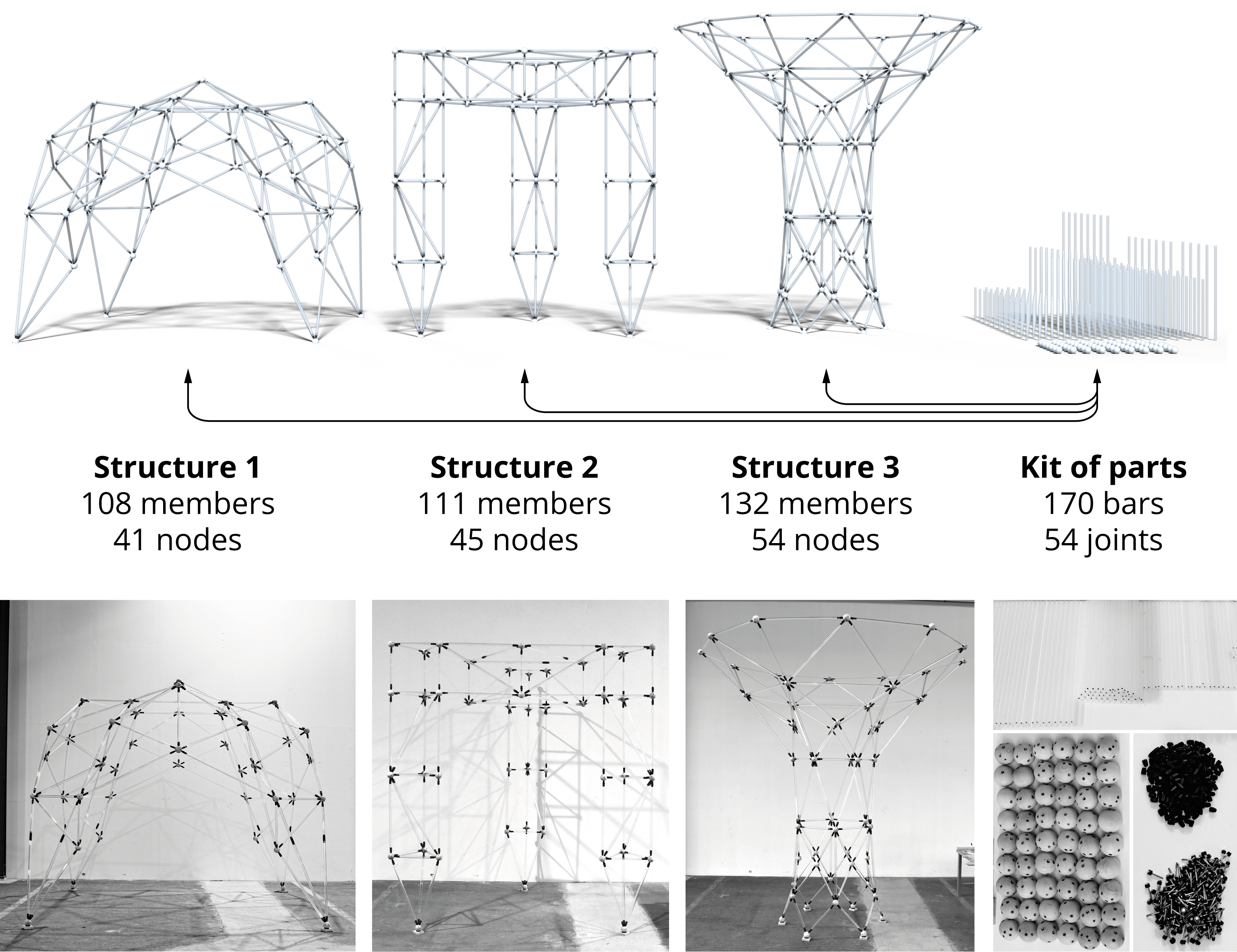

With “1-to-3”, we show the design of one bespoke kit of parts to build three structures of different typology and form. The project as part of an international exhibition organized at the annual symposium of the International Association for Shell and Spatial Structures (IASS), which took place from 06.10. – 10.10.2019 in Barcelona, Spain.

Motivation

Because of their large material mass and energy-intensive manufacturing, load-bearing systems contribute a large share of total building embodied energy and carbon. More than that, structures are often conceived only for a sole location and purpose. At their end-of-life they are demolished and only the material is recovered (recycling). Instead, we could reduce environmental impacts substantially if we design structures today that can be disassembled in the future and their parts reconfigured to fit a new purpose.

Method

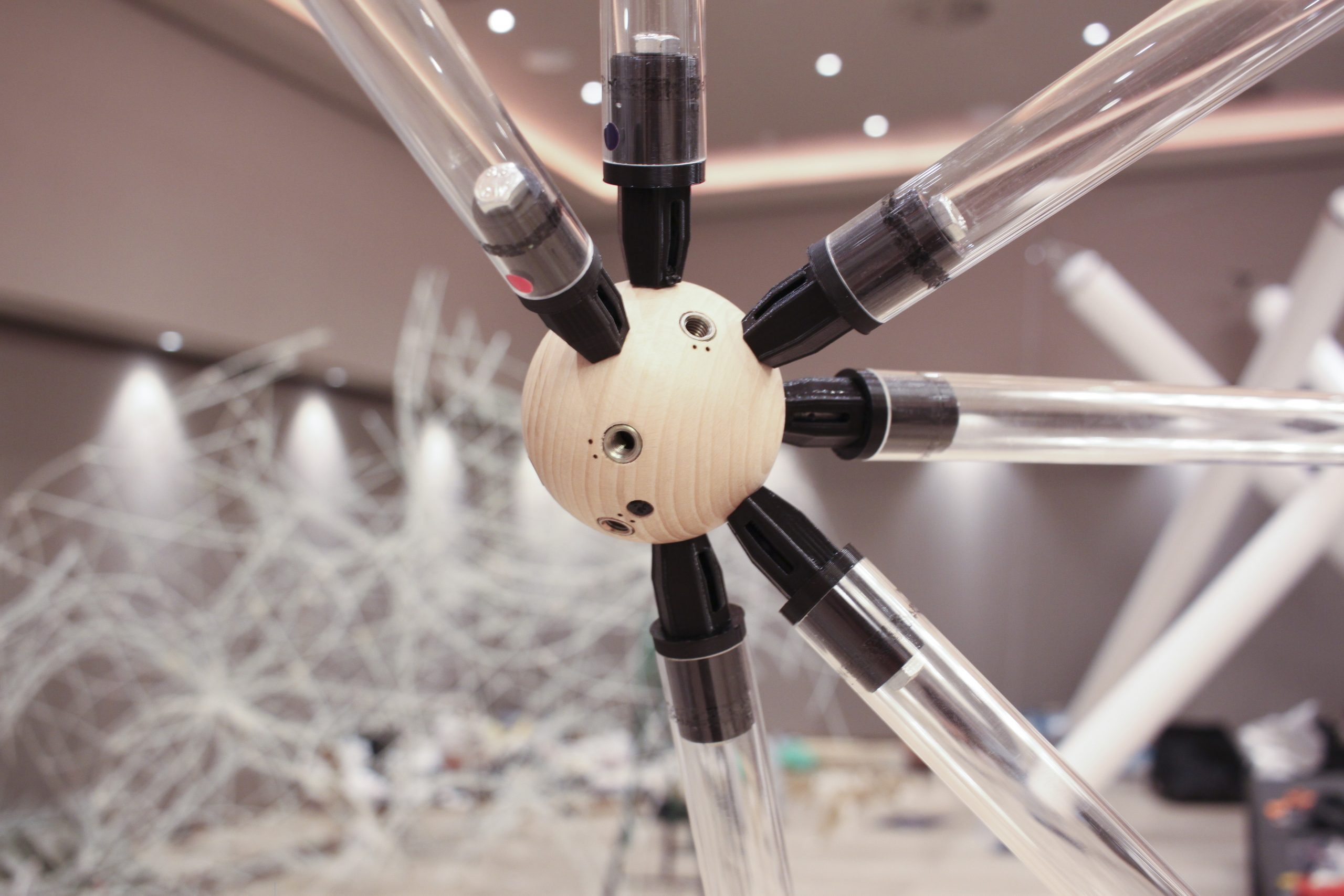

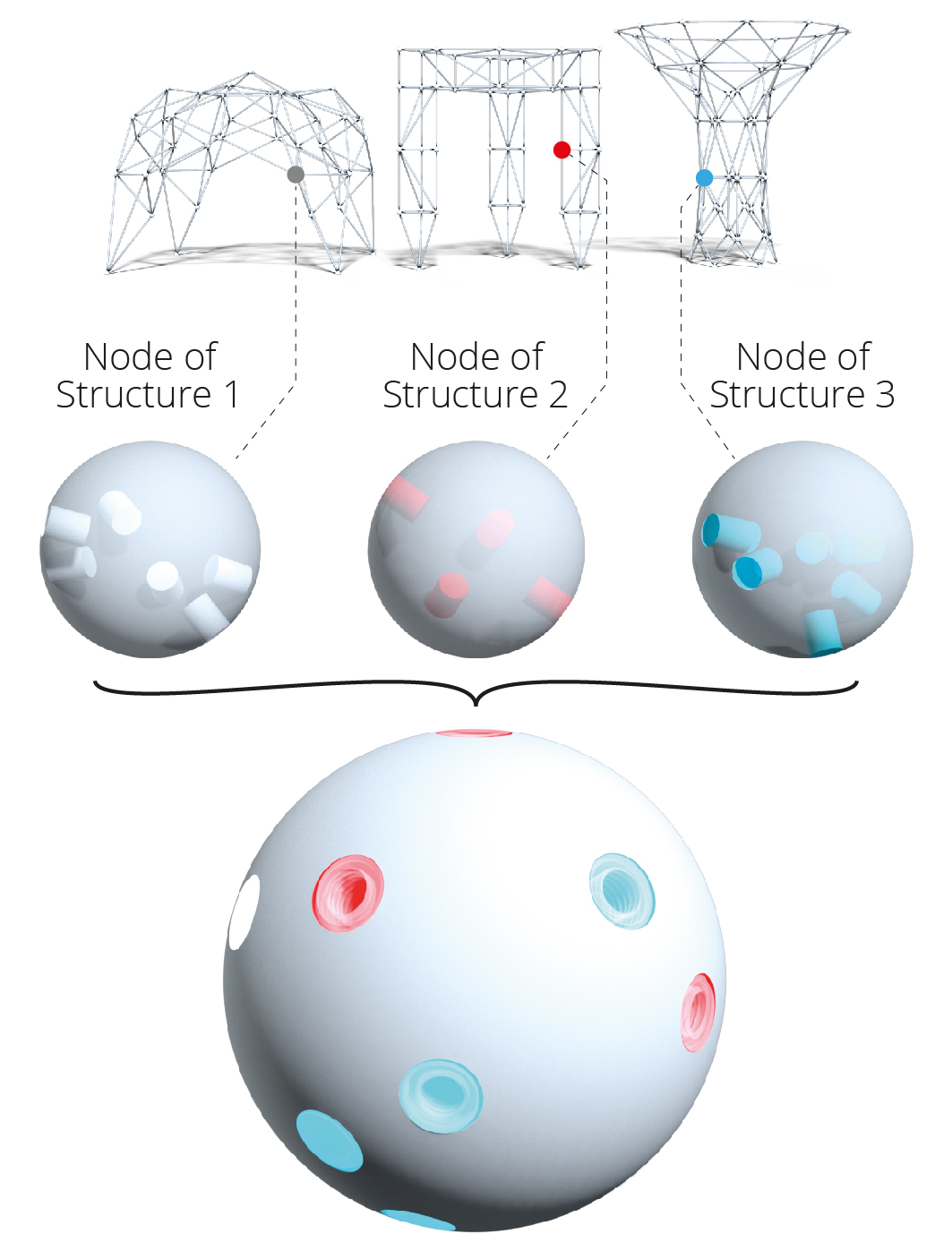

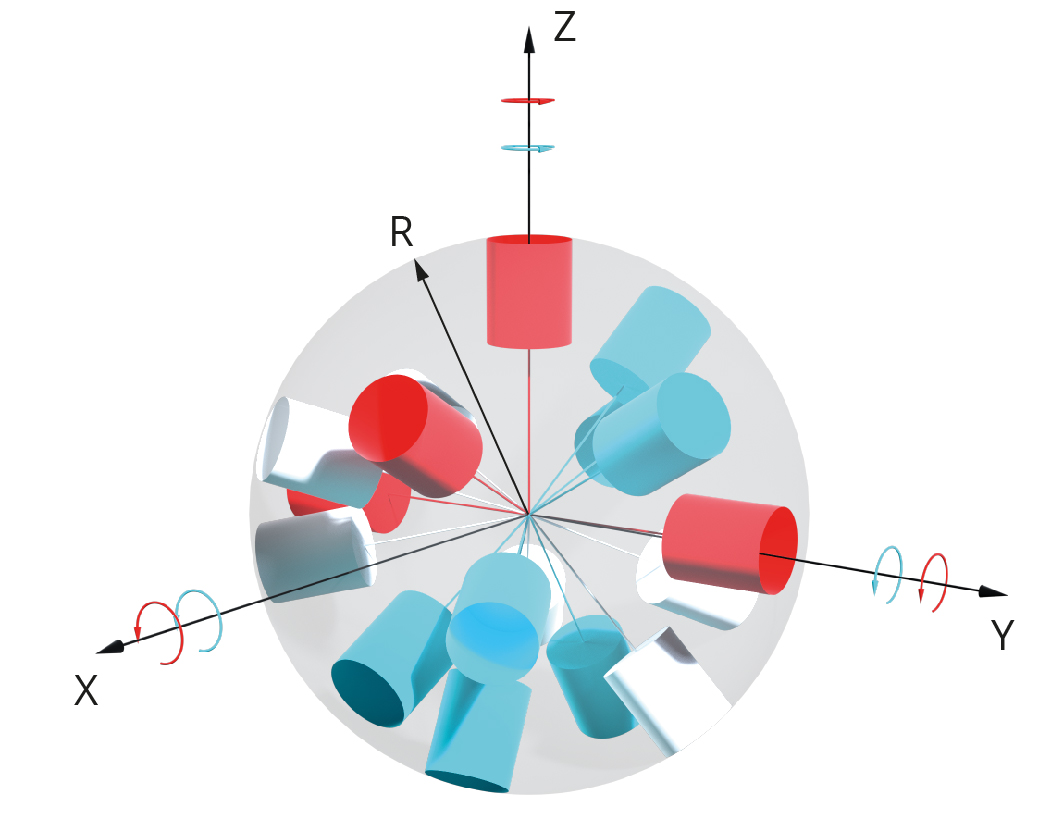

As a response, we developed computational tools and fabrication methods to design kit-of-parts structures whose members and joints can be reassembled in different configurations, similar to ‘Lego’ or ‘Mecano’ toys. The underlying design methodology has been recently presented in Jan Brütting’s Hangai Prize Paper “Form follows availability – Designing structures through reuse”. In the case of these pavilions, the three systems are space trusses with linear members and spherical joints. The bars are tubes of six unique lengths. The spherical joints have bespoke hole-patterns to allow their reuse and to connect bars of all three structures. To allow the reuse of bars in multiple configurations, the geometry of the structures as well as the kit-of-parts element lengths must be form-found simultaneously. In other words, the structure geometry is optimized such that the distance between nodes is exactly matching the available bar lengths, where in turn those bar lengths are optimized to fit the structures geometries. The main objective of this process is to maximize the number of times kit-of-parts elements can be reused in different structures. Further, the reuse of joints is permitted: the unique connection patterns of selected nodes in each of the three structure are merged into one spherical joint. An optimization method adjusts the hole-pattern sets such that no overlap between connected bars exists.

Fabrication

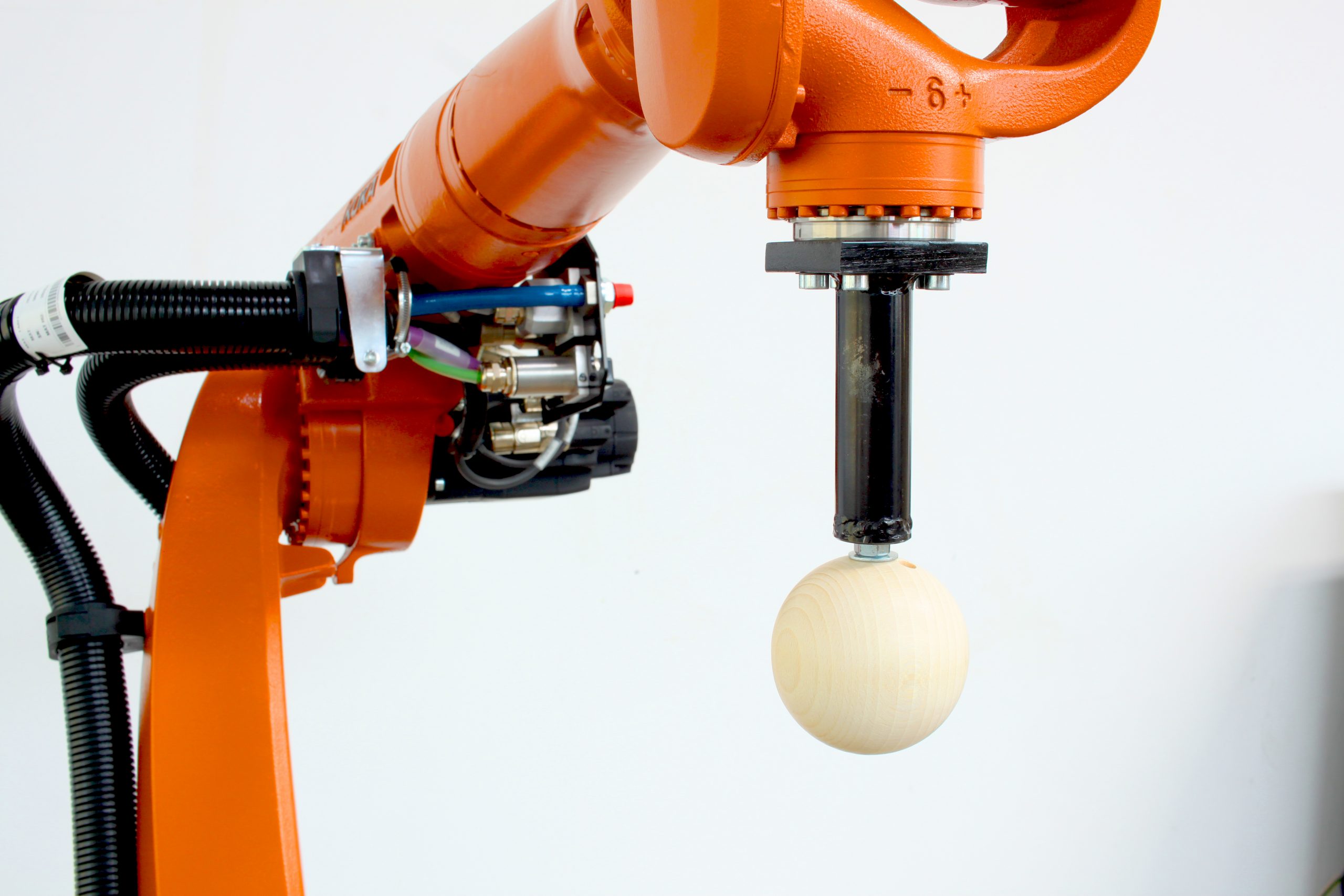

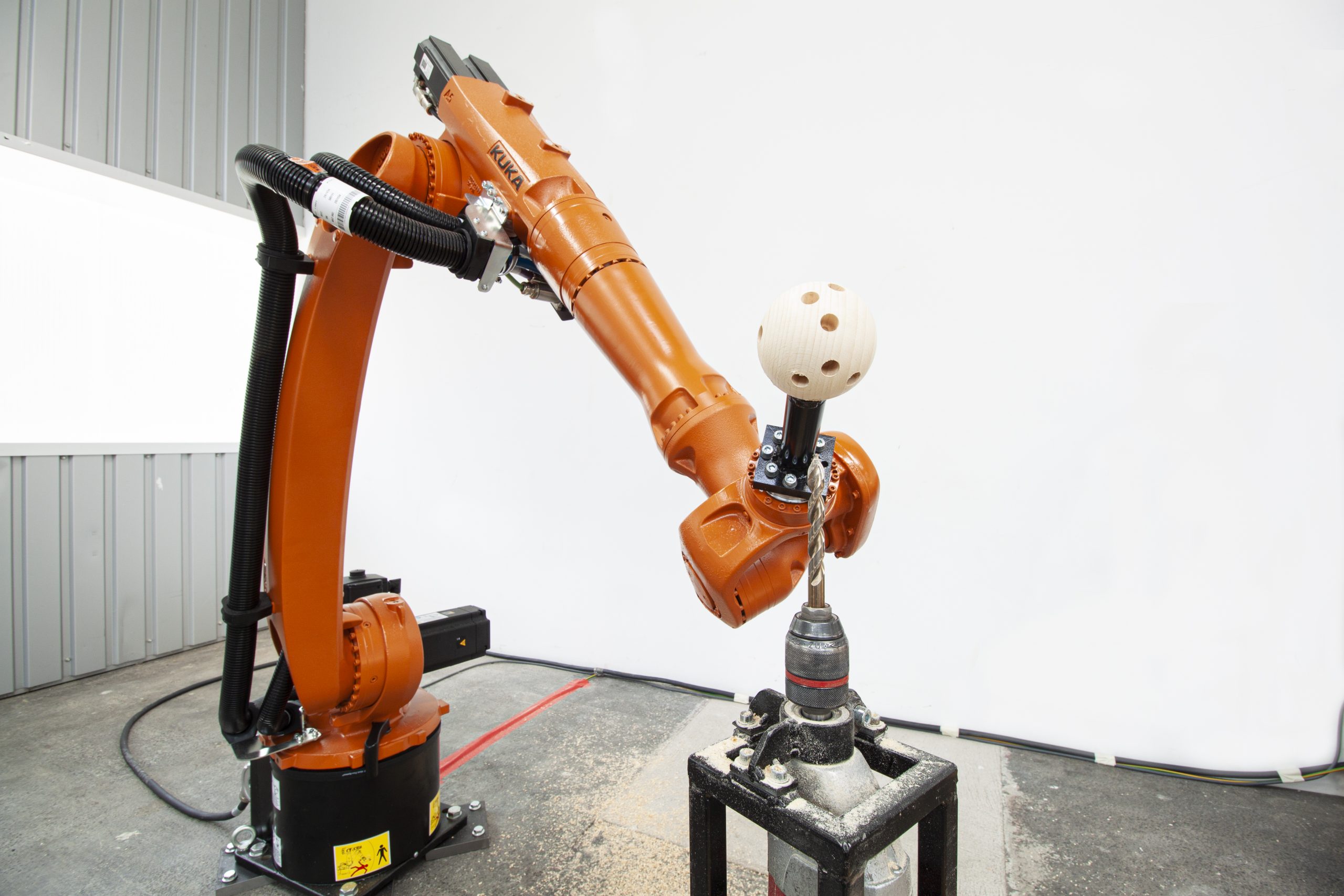

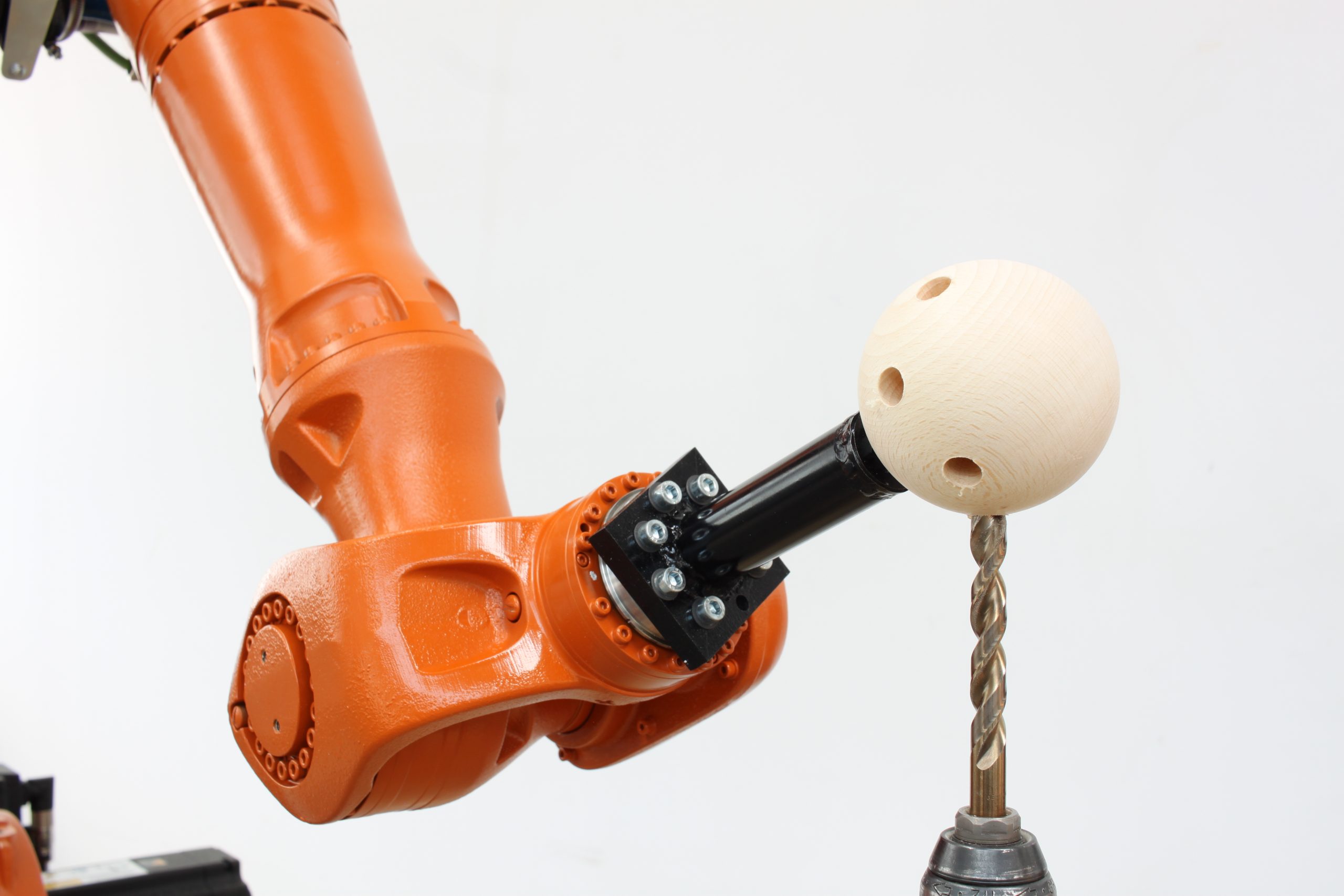

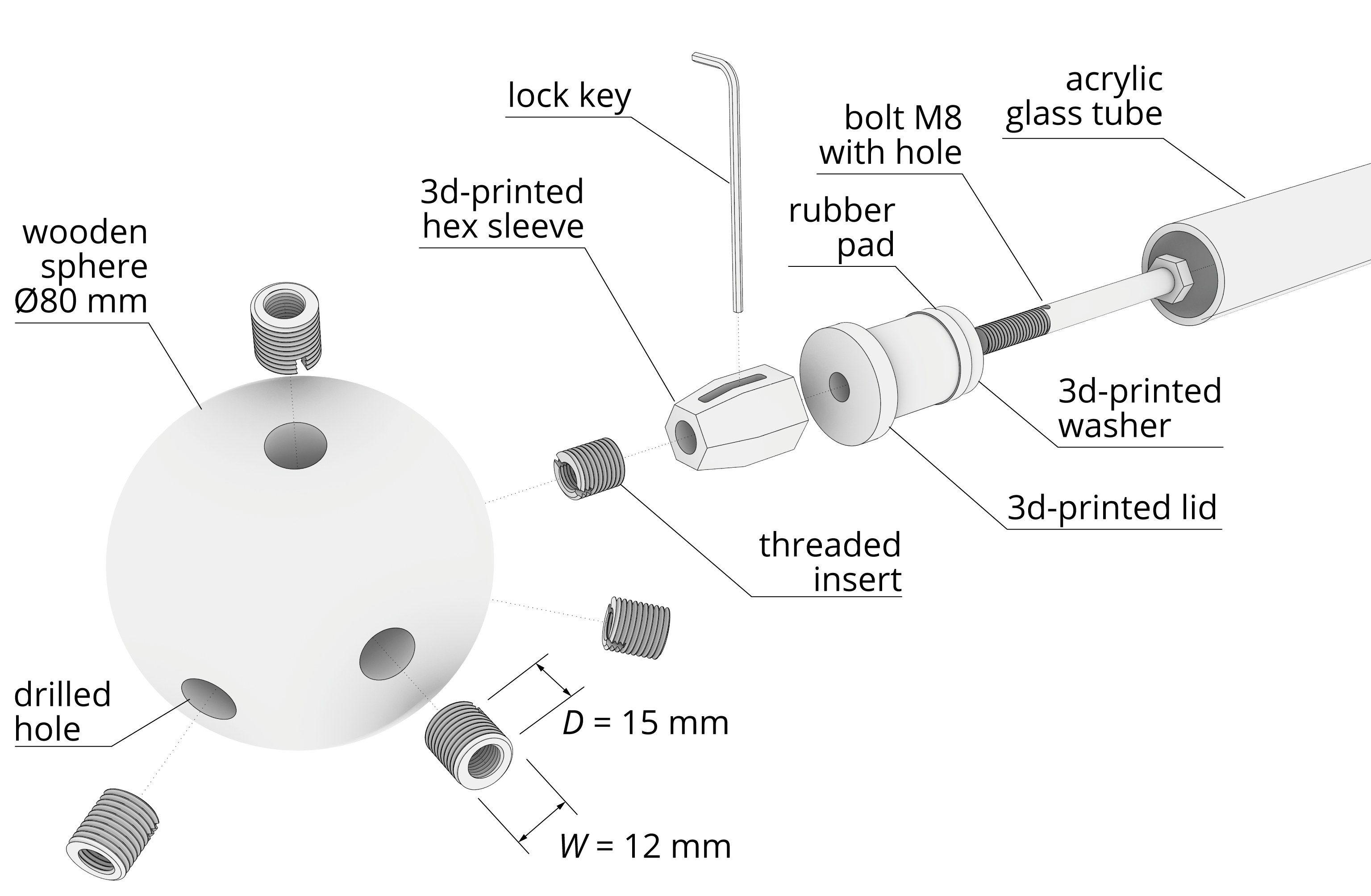

The joints are made from ø80 mm wooden spheres. To manufacture the unique, spatial hole-patterns of each joint, the spheres are attached to the flange of a KUKA KR16 industrial robot and maneuvered onto a stationary drill. In each hole threaded inserts permit the connection of the tubes with bolts. Between spheres and tubes custom 3d-printed connectors allow a reversible connection between all parts that allows an easy dis- and reassembly.

Outlook

The pavilion demonstrate the potential of the proposed method to design multi-purpose, multiple-life cycle structures. The proposed design and fabrication methods can easily be up-scaled to existing space-truss systems to design structures for temporary or recurring events, reducing substantially their environmental impact.

Acknowledgements

Special thanks belongs to Claude-Alain Jacot for the manufacturing of bespoke tools and his technical support. Further support by smart living lab, KUKA Switzerland, Debrunner Acifer and Opitec.

Motivation

Because of their large material mass and energy-intensive manufacturing, load-bearing systems contribute a large share of total building embodied energy and carbon. More than that, structures are often conceived only for a sole location and purpose. At their end-of-life they are demolished and only the material is recovered (recycling). Instead, we could reduce environmental impacts substantially if we design structures today that can be disassembled in the future and their parts reconfigured to fit a new purpose.

Method

As a response, we developed computational tools and fabrication methods to design kit-of-parts structures whose members and joints can be reassembled in different configurations, similar to ‘Lego’ or ‘Mecano’ toys. The underlying design methodology has been recently presented in Jan Brütting’s Hangai Prize Paper “Form follows availability – Designing structures through reuse”. In the case of these pavilions, the three systems are space trusses with linear members and spherical joints. The bars are tubes of six unique lengths. The spherical joints have bespoke hole-patterns to allow their reuse and to connect bars of all three structures. To allow the reuse of bars in multiple configurations, the geometry of the structures as well as the kit-of-parts element lengths must be form-found simultaneously. In other words, the structure geometry is optimized such that the distance between nodes is exactly matching the available bar lengths, where in turn those bar lengths are optimized to fit the structures geometries. The main objective of this process is to maximize the number of times kit-of-parts elements can be reused in different structures. Further, the reuse of joints is permitted: the unique connection patterns of selected nodes in each of the three structure are merged into one spherical joint. An optimization method adjusts the hole-pattern sets such that no overlap between connected bars exists.

Fabrication

The joints are made from ø80 mm wooden spheres. To manufacture the unique, spatial hole-patterns of each joint, the spheres are attached to the flange of a KUKA KR16 industrial robot and maneuvered onto a stationary drill. In each hole threaded inserts permit the connection of the tubes with bolts. Between spheres and tubes custom 3d-printed connectors allow a reversible connection between all parts that allows an easy dis- and reassembly.

Outlook

The pavilion demonstrate the potential of the proposed method to design multi-purpose, multiple-life cycle structures. The proposed design and fabrication methods can easily be up-scaled to existing space-truss systems to design structures for temporary or recurring events, reducing substantially their environmental impact.

Acknowledgements

Special thanks belongs to Claude-Alain Jacot for the manufacturing of bespoke tools and his technical support. Further support by smart living lab, KUKA Switzerland, Debrunner Acifer and Opitec.

Project team

Concept

Jan Brütting, Corentin Fivet

Kit-of-parts structural optimization

Jan Brütting, Gennaro Senatore (IMAC, EPFL), Corentin Fivet

Design and Build team

Jan Brütting, Ioannis Mirtsopoulos, Alex Muresan, Catherine De Wolf, Prateek Kumar, Nicholas Montagne, Claude-Alain Jacot, Corentin Fivet

Documentation and Video-Editing

Jan Brütting, Cornelius Carl

RELATED PUBLICATIONS

Journal Paper

Design and fabrication of a reusable kit of parts for diverse structures

Jan Brütting, Gennaro Senatore, Corentin Fivet

Automation in Construction, vol. 125, article 103614, 2021